Direct Mail Processor Innovation on Show at Chicago Print Expo

30th August 2017

From September 10-14, Print 2017 in Chicago offers industry insiders the opportunity to explore the latest trends in the international print and media industry. BÖWE SYSTEC will be demonstrating the benefits of its inserting technology for the Transactional and Direct Mail market with the high-performance inserting system Fusion Cross and the North American debut of the Direct Mailer mid-range inserter at booth 841 under the motto ‘A step ahead’.

Leading the way is the high-performance inserting system Fusion Cross, which has continued to evolve to meet customer requirements since its successful launch in 2012. The Fusion Cross has proven that a Single Machine Type Strategy (SMTS) has a revolutionary impact for Transactional and Direct Mail processors with a replacement ratio of up to four to one legacy inserting systems. It can automatically changeover between any folded or Flat envelope size in only a few minutes and includes the user-friendly BÖWE Cockpit operating system with easy to configure Recipe driven application programming. This market-proven inserting platform provides the Direct Mail segment with unprecedented throughput and efficiency, dramatically changing the capabilities for their unique challenges and complexities.

Through continued R & D investment, the Fusion Cross now offers the most flexible enclosure feeding options for the demanding inserts that Direct Mailers face. The unique vacuum-friction enclosure feeder is capable of processing single page inserts through rigid, thick and heavy items with unparalleled abilities. The rotary feeder expands the capabilities for specialized inserts and both feeders can be equipped with an autoloader to expand their feeding capacity. Thanks to the open device carrier concept, the feeders can optionally be exchanged in minutes to accommodate specialised requirements.

The unique inserting Flow-Principle of the Fusion Cross reduces the relative speed between the envelope and the inserts during the insertion process by a factor of 4.5. This allows for a unique, patented, stable and gentle inserting process. In addition, three envelopes are filled at the same time which improves the overall operating efficiency to a new level. This higher efficiency applies to all envelope formats and thicknesses. The ability to replace fleets of older single purpose inserters with fewer high-speed, full integrity inserting platforms can now be realized yielding full production flexibility and a reduction in manpower and floor space.

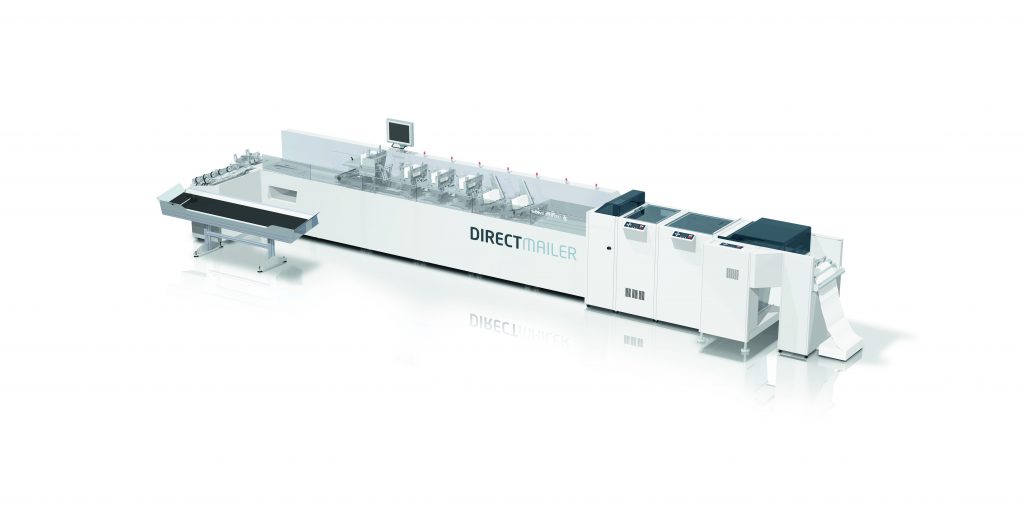

North American debut of the Direct Mailer

The North American debut of the Direct Mailer at Print 2017 in Chicago now provides the integrity and flexibility desired by the mid-range inserting market segment. The system is available in two basic versions: The Direct Mailer for formats up to C5 and 6 x 9 is ideal for conventional mail processing with its powerful performance of up to 15,000 envelopes per hour. With an output of up to 10,000 or 8,000 envelopes per hour respectively, the C4 and Flats (9 x 12) version of the Direct Mailer offers the full flexibility of a multi-format inserter with full integrity and item level tracking. Flexible configurations starting from a base only inserter or with the full complement of BÖWE SYSTEC’s cut-sheet and continuous form input channels. Thanks to the self-explanatory BÖWE Cockpit control software, the Direct Mailer can be operated easily and intuitively. This provides the investment protection and equipment flexibility sought after by production facilities.